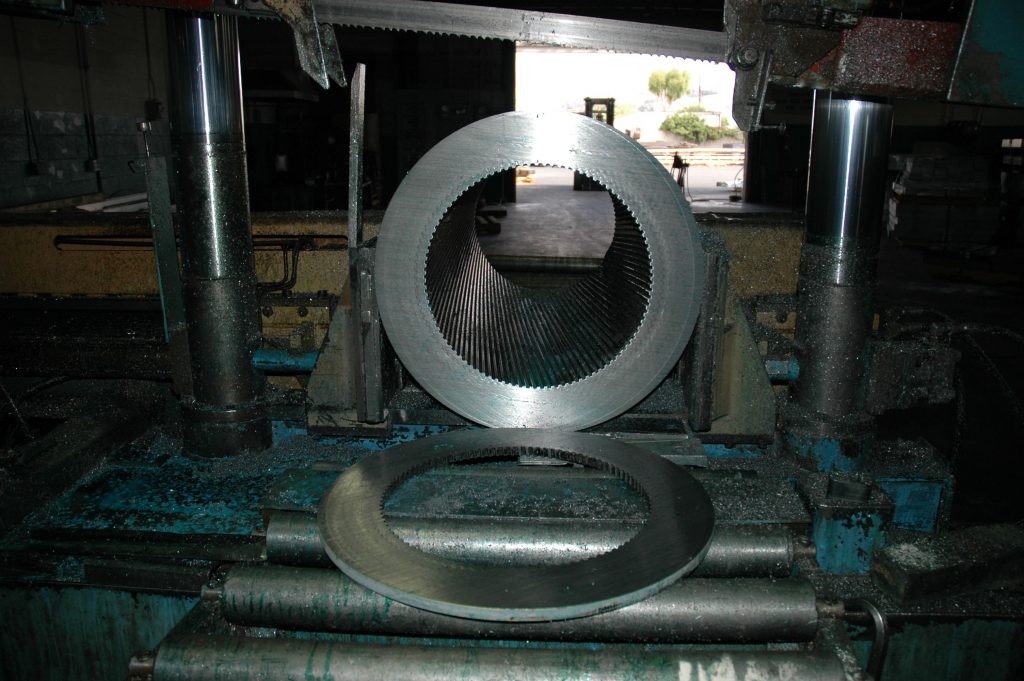

Metal Cutting Service

Metal Cutting Service (MCS) specializes in taking large pieces of metal and cutting them into smaller pieces of metal that are then machined into the final size that are used in everything from computer chip manufacturing to aerospace and defense parts. MCS is a small, lean manufacturing company in California that is a third and last generation family owned business. In April 2020 we spoke with owner David Viel, “I have been doing this all my life, and have loved being in this business. We are here to serve others.”

“There are so many ways that the business community can serve, as we are seeing today during this pandemic. We are all donating time and resources to things such as community and secular food banks, medical supplies, time for charitable work, and many other opportunities. It is a time to share resources, not hoard them. And as long as we are able to, we plan on keeping all of our employees, and paying them all of their benefits including their insurance, which is a tremendous cost, but also a blessing.”

Metal Cutting Service takes pride in how they do business:

Relationships with employees

“After a certain amount of time, we are more like a family – we are not perfect, but we have more than just an employer-employee relationship.” David explains. More than 50% of their employees have been with MCS for more than 25 years — and that does not happen by accident. It takes work and a purpose to be around people for that long.

Relationship with NASA

David proudly shares, “I keep a 50+ year-old bottle of Tennessee Whiskey on my credenza that has never been opened. It was given to us by NASA back in 1968 when we participated in a crash program to get the new landing pads made for the Apollo 11 moon landing.” MCS was part of a team that designed, created and built the pads (still on the moon) that were used for the lander.

MCS was also involved in the NASA program for the Voyager explorer – which launched in 1977 that has recently left our solar system. “People often ask us how far we ship, and I always say, “Millions of miles!” and explain that the furthest away our parts are is out past the furthest planet. Let someone else in our field top that!”

9/11 Memorial

A more recent memorable piece of work was cutting pieces from the single standing beam that looked like a cross that was left after the Twin Towers collapsed. They cut 200 pieces (and were allowed to keep one piece).

On Working with Mophilly

David explained: “Mophilly has really helped us out when we have found ourselves in trouble, as well as when we needed regular updates.”

- “The first time we used Mophilly, we were taking a very old version of the Omnis system (I’m talking like FIVE generations old) and updating it to the current standard at the time. Mophilly did the update on time and on budget.”

- Last year MCS experienced a systems crash and found out that they had not been properly backing up their system when they thought they were. “Mophilly rescued us, and even helped us backup our system to a newer backup than even we had. And they were there to expedite our panicked emergencies when they arose, and were able to get us into a modern, updated system as well as the most current software versions of our database. For a non-techie company like ours, they were able to make the transition and updates easy to use as well as logical to someone without a technical background.”

Follow